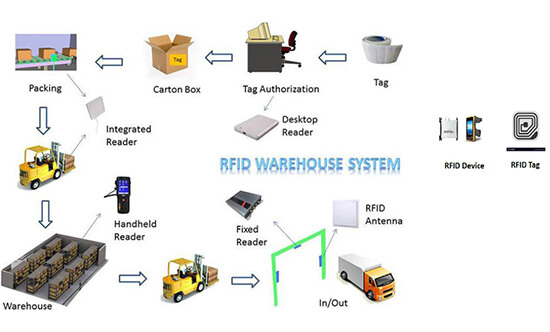

Unicom ERP Warehouse Management System (WMS), provide a comprehensive solution for managing the warehouse by way of multiple warehouses, warehouse locations, items in a specific location, batch number, pallet / carton id, receiving, put away, picking, delivery, etc. The system is supported by RFID solution.

Many functions which was conceived as impossible, become possible with the help of RFID technology. This include Pallet / Carton level inventory management. Without RFID, inventory management was restricted to Item code and Batch number.

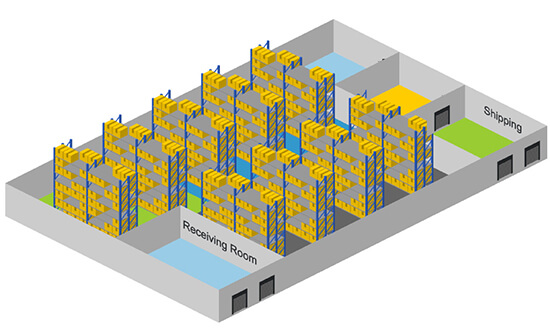

Unicom WMS provide information related to each location in the warehouse with regards to the items in the location and Cartons / Pallets in that location. In a warehouse there will be normally a receiving location and a delivery / shipping location. The shelfs are marked as Aisle / Zones. Each Aisle is further marked as columns and rows. Assume that a shelf or area is marked as ‘A0’ and it have 3 columns and 5 rows. Column ‘02’ in that shelf on row ’03’ is marked as location ‘A00203’. Unicom WMS provide such functionality to create location based on Aisle, Row and Column for easy location management.

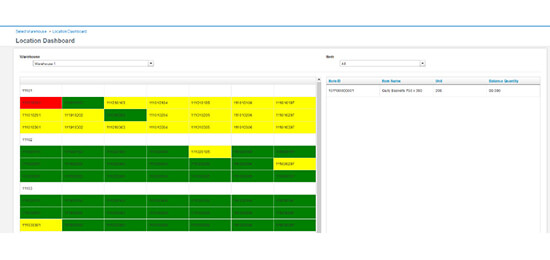

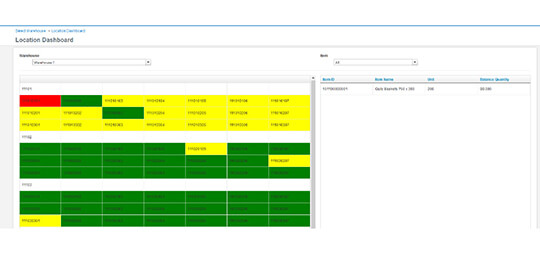

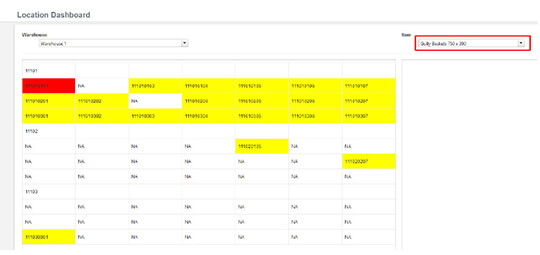

Unicom WMS provide information related to each location in the warehouse with regards to the capacity availability in the location by way of color coding. Certain location can be blocked for any further storage by reason of full capacity or some reserved materials, etc. Those locations will be displayed as Red. When a location is empty and material can be stored, it will be displayed as Green. On the other hand, if a location have material and can receive more materials it will be shown as Yellow.

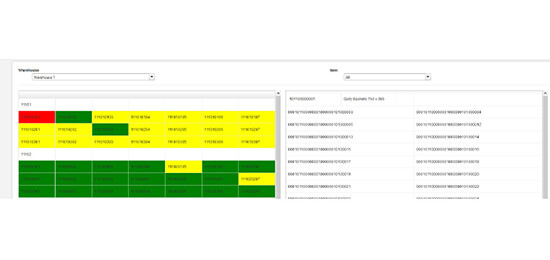

On clicking on a specific location, on selecting all items, it will display items in that location.

To locate the location in which a specific material, on selecting an item, it will show all location containing that item.

On clicking on a specific location, it will display Cartons / Pallets in that location.

RFID tag will stick to the carton / pallet, before it is moved to the storage area. When a carton / pallet passes through an RFID gate, it will read all those tags. Normally tag ID is created in the format of Item Code – Batch Number – Carton / Pallet ID. Assuming Item code is 101001 and batch number is 2013 and Carton ID is 1098, the tag id will be 101001-2013-1098.

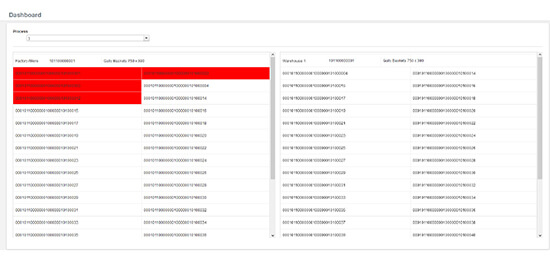

When a material is transferred from a warehouse (like production area) to another warehouse (like storage area. The RFID gate in the transferring warehouse will read all cartons / pallets, while the RFID gate in the receiving warehouse also will read all items received in that warehouse. On selecting the transfer order, it can easily identify the missing / excess cartons received in the receiving warehouse house compared to the transferring warehouse.